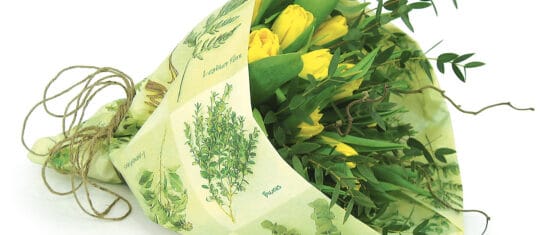

Sustainable production of packaging materials

CARCCU: YOUR GO-TO PARTNER FOR ECO-FRIENDLY PACKAGING MATERIALS

Carccu® endeavors to be a pioneer in practical ecological actions. We take the environment into account in all our operations—from start to finish. We manufacture eco-friendly packaging materials using methods that have a low impact on the environment. We also actively develop better alternatives for producing eco-friendly packaging.

CERTIFICATIONS AS EVIDENCE OF OUR COMPREHENSIVE EFFORTS TO SAVE THE ENVIRONMENT

We strive to minimize waste and environmental impact in every stage of our manufacturing process. We favor fossil-free electricity, recycle as much surplus material as possible, and promote the circular economy. We use only responsibly produced and environmentally friendly materials in our production. All waste generated in production is recycled, and only household waste ends up in landfills. We deliver high-quality products in small batches to our customers, which helps them to reduce waste also. Many of the products we manufacture are recyclable or biodegradable.

Carccu® has worked diligently for the environment, and as a result, the company has been awarded the ISO 9001 quality system certificate, the ISO 14001 environmental system certificate, as well as the FSC® Chain of Custody (CoC) certification developed by the Forest Stewardship Council® and the PEFC Chain of Custody (CoC) certification developed by the Programme for the Endorsement of Forest Certification.

FSC® Chain of Custody certification verifies that the certified materials are tracked and separated from non-certified materials throughout the production process, ensuring compliance with strict environmental, social, and economic sustainability standards.

Similarly, the PEFC Chain of Custody certification ensures that the wood-based raw materials used in Carccu®’s products can be traced from certified forests through the entire supply chain, maintaining transparency and accountability in sustainable sourcing.

HIGH QUALITY AND ENVIRONMENTALLY FRIENDLY INKS

We use only environmentally friendly and high-quality water-based inks for package printing. The inks we use comply with the Swiss Ordinance, and we also use powerful flexographic printing machines and agile production processes. These factors ensure we produce paper packaging cost-effectively and in an eco-friendly way.

Waste inks are mixed into black pigment, which can then be used to print kraft paper. The waste inks from this process are dried to minimize the amount of waste.

PRODUCTION SIDE STREAMS ARE RECYCLED

At Carccu®, we strive to minimize the amount of material ending up in landfills across all our operations, which is why all production side streams are carefully sorted. Our overall recycling rate is 99.9%, and 99.5% of side streams are recovered for further use. However, we are committed to continuous improvement, with the goal of further reducing the amount of waste sent to landfill. Currently, 52.5% of the production side streams are utilized as raw materials and processed into new products.

We deliver any wastepaper and cardboard generated in production to the paper mill where it is used to make new paper. This paper is then made into paper cores that we use in our production. We strive to keep materials in circulation for as long as possible. This is circular economy at its best!

We lower our impact on the environment by using existing materials as long as possible, instead of constantly producing new ones. We also sell some of the usable surplus material generated in production to other companies as packaging materials. All metal and plastic waste is also recycled. Inks are delivered to us in metal barrels, and all our empty barrels are used by another company in their own production. The rest of the metal waste is recycled for the metal industry and manufacturing new products. The PE plastic stretch film used on pallets is made into new plastic raw material.

WE ARE ENERGY EFFICIENT

While recycling and using environmentally friendly materials in production is very important, we can also operate in an environmentally sound manner in many other ways as well. These include various energy saving measures and using fossil-free energy. We have used LED lights – more energy efficient and more environmentally friendly than traditional alternatives – in our facilities since 2012. We use climate-neutral, fossil-free electricity in our production, which means that it doesn’t increase the amount of carbon dioxide in the atmosphere. What’s more, we are constantly looking for new ways to save energy.